Premium Dairy Beef Feed

We utilize the most recent research available to keep your dairy beef herd healthy and productive. We offer multiple feeding programs to suit your needs. We have dairy beef specialists to provide on-farm consultation as well.

Dairy Beef Program Summary

| Stating Age | Birth (in months) | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Starting weight, lbs | 88 | 115 | 175 | 250 | 340 | 435 | 530 | 625 | 725 | 820 | 910 | 1000 | 1090 | 1180 | 1265 | 1350 |

| End weight, lbs | 115 | 175 | 250 | 340 | 435 | 530 | 625 | 720 | 820 | 910 | 1000 | 1090 | 1180 | 1265 | 1350 | Market |

| Monthly Weight Gain, pounds | 27 | 60 | 75 | 90 | 95 | 95 | 95 | 95 | 95 | 90 | 90 | 90 | 90 | 85 | 85 | 85 |

| Dry Feed | Milk or milk replacer and Dairy Beef Starter | Gradually wean and enncouraging more dry feed intake | 16% Dairy Beef Grower | 16% transitioned to a 14% Dairy Beef Grower | 14% Dairy Beef Grower | 2 lbs of NEMO Steer Stuffer Pellet plus ad lib whole shelled corn | 1 lb of NEMO Steer Stuffer Pellet plus ad lib whole shelled corn | 1 lb of NEMO Steer Stuffer Pellet plus ad lib whole shelled corn | 1 lb of NEMO Steer Stuffer Pellet plus ad lib whole shelled corn | 1 lb of NEMO Steer Stuffer Pellet plus ad lib whole shelled corn | 1 lb of NEMO Steer Stuffer Pellet plus ad lib whole shelled corn | 1 lb of NEMO Steer Stuffer Pellet plus ad lib whole shelled corn | 1 lb of NEMO Steer Stuffer Pellet plus ad lib whole shelled corn | 1 lb of NEMO Steer Stuffer Pellet plus ad lib whole shelled corn | 1 lb of NEMO Steer Stuffer Pellet plus ad lib whole shelled corn | 1 lb of NEMO Steer Stuffer Pellet plus ad lib whole shelled corn |

| Milk replacer consumption, lbs of powder | 38 | 12 | - | |||||||||||||

| Daily dry feed consumption, lbs | 1 to 2 | 2.5 to 5 | 7.2 | 9 | 12 | 14 | 14.5 | 15.5 | 16.5 | 17.8 | 19.2 | 21.5 | 22.8 | 24.1 | 25.3 | 26.5 |

| Monthly dry feed consumption, lbs | 45.75 | 114.375 | 219.6 | 274.5 | 366 | 427 | 442.25 | 472.75 | 503.25 | 542.9 | 585.6 | 655.75 | 695.4 | 735.05 | 771.65 | 808.25 |

| Anticipated conversion (Feed: Gain) | 1.7 | 1.9 | 2.9 | 3.1 | 3.9 | 4.5 | 4.7 | 5.0 | 5.3 | 6.0 | 6.5 | 7.3 | 7.7 | 8.6 | 9.1 | 9.5 |

| Milk replacer cost, $ | 49.4 | 15.6 | ||||||||||||||

| Dry Feed Cost, $ / month | 7.92 | 19.79 | 34.47 | 43.09 | 51.77 | 43.08 | 36.41 | 38.39 | 40.37 | 42.95 | 45.73 | 50.29 | 52.86 | 55.44 | 57.82 | 60.20 |

| Feed Cost/lb of gain | 2.12 | 0.59 | 0.46 | 0.48 | 0.54 | 0.45 | 0.38 | 0.40 | 0.42 | 0.48 | 0.51 | 0.56 | 0.59 | 0.65 | 0.68 | 0.71 |

| BIRTH TO FINISH FEED COSTS: | 745 | |||||||||||||||

| Initial calf cost | 65 | |||||||||||||||

| Bedding ($0.12/d) | 54 | |||||||||||||||

| Vaccinnes and health costs | 12 | |||||||||||||||

| Implanting | 10 | |||||||||||||||

| Labor ($0.30/d) | 135 | |||||||||||||||

| Death loss (est 6%) | 25 | |||||||||||||||

| Feed costs | 740 | |||||||||||||||

| TOTAL ESTIMATED COSTS | 1041 | |||||||||||||||

| EXPENSES PER POUND OF LIVE WEIGHT | 0.771 |

Young Calf Guide: Birth to 5 Months

Dairy steers and dairy-beef crossed animals are a valuable co-product to dairy production. When fed and managed correctly, our clients can grow new born calves to well over 400 pounds before they reach 5 months old. Average daily gain will be 2.5 to 3 pounds per day.

To achieve the best return on investment from dairy beef, one needs to manage them different than a native beef animal.

NEMO Feed has specially formulated supplements that are mixed with whole shelled dry corn to become a complete feeding program from birth to finishing. For ease of management, forage of any type is often never fed to these animals.

FEEDING PROGRAM

Feeding Directions

To make 1 ton of feed. Carefully mix ingredients according to the appropriate feeding table shown below. Take care not to overmix so the pellets remain intact. The complete feed will look like the picture above.

The daily intake column is just a guide, offer feed free choice so that calves never run out and expect intake to fluctuate with environment conditions.

Feed alongside 20/20 milk replacer for the first 6 weeks of life. Feed 3 quarts of milk replacer twice daily. Whole milk, or a higher spec milk replacer are acceptable, but generally speaking a 20/20 is adequate to meet calf maintenance needs until dry feed consumption ramps up.

Making a Textured Dairy Beef Feed on Farm Using NEMO’s 28% DB Pellet

| Animal Weight & Age | NEMO Feed 28% DB Pellet | Oats | Roasted Soybeans | Whole Shell Corn | Approx. Daily Intake Range |

| 85-175 lbs Birth-2 mths | 610 | 275 | 225 | 890 | 1-5 lbs |

| 175-295 lbs 2-3.5 mths | 550 | 275 | 125 | 1,050 | 5-10 lbs |

| 295-435 lbs 3.5-5 mths | 500 | 60 | 65 | 1,375 | 10-14 lbs |

If your farm does not have roasted soybeans on hand, use NEMO Feed’s 30% DB Concentrate Blend. This is a texturized blend and contains roasted beans.

| Animal Weight & Age | NEMO Feed 30% DB Blend | Oats | Whole Shell Corn | Approx. Daily Intake Range |

| 85-175 lbs Birth-2 mths | 610 | 275 | 825 | 1-5 lbs |

| 175-295 lbs 2-3.5 mths | 725 | 265 | 1,010 | 5-10 lbs |

| 295-435 lbs 3.5-5 mths | 600 | 75 | 1,325 | 10-14 lbs |

For feeding animals larger than 435 pounds, see NEMO Feed’s Grower & Finisher Guide.

Noteworthy Features of NEMO Dairy Beef Formulas

- Unlike competitor products, the NEMO Feed Dairy Beef line does not contain ingredients to limit intake. Rather we aim to achieve the highest intake possible which translates into larger daily weight gain.

- Proper use of ionophores to improve animal performance and control coccidiosis.

- Targeted use of micro ingredients to naturally promote gut health and reduce pathogen load.

- Formulated to supply adequate levels of macro minerals due to low mineral content of corn grain.

- Heavily fortified with a blend of vitamins, as well as organic, hydroxy, and sulphate minerals to support health and growth.

- Use of proven mold inhibitor to extend shelf life.

- During warm weather, Diflubenzuron is included to help reduce fly populations.

MANAGEMENT BEST PRACTICES

Newborn Calf Care

Calves are born with no immunity so they depend on antibodies in colostrum, do your best to source calves that received colostrum at birth.

Overall cleanliness of feeding equipment, pen, and bedding is paramount to animal health, especially early in life.

Refresh feed daily, which involves pouring out the old feed to remove pellet fines, and unconditioned feed. That day old feed can be recycled to older calves.

Shallow buckets for dry feed work better earlier in life so that calf doesn’t have to lower their head into a bucket, and also because there is less surface area for flies to land on.

Vaccinate/Dehorn/Castrate Schedule

Work with a veterinarian that has calf raising experience to fine tune a vaccination protocol. The protocol will look something like this:

Day 1:

- Respiratory vaccine

- Dehorn & dissolve Meloxicam* in milk

Day 2:

- Dissolve Meloxicam* in milk

Day 7:

- Clostridium C/D and Tetanus vaccine

- Castrate & dissolve Meloxicam* in milk

Day 8:

- Dissolve Meloxicam* in milk

Day 35:

- Respiratory vaccine

Dehorning: Clip horn buds and apply dime-sized amount of paste dehorner to horn buds. Dehorn after feeding.

*Meloxicam is used to help alleviate pain. Dosage: 3 15 mg tablets per calf.

FARM (Farmers Assuring Responsible Management) is a program focused on animal well-being, particularly pain management during dehorning and castration. Follow FARM for the latest recommendations on these topics.

Milk Feeding

Closely follow label directions for mixing milk replacer and deliver to the calf at approximately 103° F. Feed consistent amounts at regular intervals. Three quarts twice daily performs well, but we have seen other volumes work. Consistency is important.

Clean and sanitize bottles, nipples, buckets and all mixing equipment with appropriate chemicals and hot water after EACH use. Allow to dry after each wash.

Weaning

Weaning should be based on dry feed intake and not on calf age. Do not wean until >2.5 pounds of dry feed is being consumed consistently.

At around 6 weeks of age, gradually decrease the volume of milk being fed over the course of a few days. A common strategy at this age is to half the milk volume fed by feeding milk once per day instead of twice, and this will work. However, we have found that sticking with twice daily milk feedings, but feeding half the milk volume, seems to reduce stress on the calf through the weaning phase.

Weaning will encourage more dry feed intake. Make sure plenty of water is available. Don’t change housing at time of weaning. Allow a week or two for calves to adjust before changing housing.

Bedding

Proper bedding is a cornerstone of the program. The quality of bedding dictates calf health and growth. Bed calves as if you were spending the night on it. Plan to refresh bedding often.

The most effective bedding sources:

- Are not dusty

- Absorb moisture

- Insulate the calf during cold weather

- Do not harbor flies in the summer

Common calf bedding sources are straw, wood shavings, sand, soybean stubble, and rice hulls.

Universities have proven a direct connection between bovine respiratory disease (BRD) and the quality of calf bedding. Dry bedding yields less respiratory disease.

For animal health, dry bedding is just as important in the summer as it is in the winter months.

Suggested Cleaning Protocol

Feeding equipment has direct contact with the calf’s mouth so cleaning and disinfecting is crucial to preventing the spread of disease.

- Rinse all equipment/utensils with warm water (110 °F) removing organic milk residue before washing.

- Soak the equipment/utensils in hot water (140 °F) with a 1% chlorinated alkaline detergent (CIP) (pH of 10-11) for approximately 20-30 minutes.

- Wash vigorously with a brush for 1-2 minutes.

- Rinse with a 50 ppm chlorine dioxide solution in warm water (110 °F) for about 5 minutes to sanitize. Then a weekly rinse of equipment with an acid (pH of 3-4) to control milk stone.

- Allow the equipment to dry before using again. Avoid stacking upside down on a concrete floor or on any solid surface, as this can inhibit proper drying and drainage.

Building Design

House calves in an environment that is well bedded and ventilated. If you can smell ammonia, ventilation and sanitation are inadequate. Vented roof ridges help dirty air escape.

Dairy animals have thinner hides so more shelter is needed compared to traditional beef calves.

Sufficient space per calf (stocking density) is the single most important determinant of air quality in calf barns.

Airborne bacterial density studies show barns should be sized for approximately 30 to 40 square feet of bedded space per calf. Some calf growers try higher stocking densities, allowing less square foot per calf, but barns with less square feet per calf experience higher death loss and slower gains.

In group housing systems, aim for all calves to have access to feed at the same time to avoid the situation where the smallest, most timid calves do not get to eat until the larger, higher-ranking calves have already sorted the feed.

Water

Clean water is the most import nutrient of the entire feeding program, so design buildings to provide access to plenty of clean fresh drinking water. Also design buildings so water troughs can easily be cleaned.

- Water is a key factor to maintain body temperature (during summer and winter). Water also aids in digestion, transports nutrients, and flushes toxins.

- Calves that receive rural water typically outperform calves receiving water from wells or ponds.

- When choosing water troughs for calves be sure waters are not too tall (Small calves may have difficulty reaching water if the trough is placed on the feed table).

- If waters will be placed in the bedded pack area, calves should only have access to the waterer from the feed alley to reduce the spoilage of bedding. Building a guard between water access and the bedded pack area avoids creating more wet bedding which influences the amount of dry resting space available.

Barn Cleaning

The barn should be thoroughly cleaned between calf groups. Remove all old bedding and then brush, sweep, and scrape to remove other organic material.

Allowing the barn ten days to rest before repopulating helps break any disease life cycle. Repopulate the new calves into a clean barn with fresh dry bedding.

Calf Grouping Is Important

Group calves according to size and age. This is best achieved when barns can be filled quickly. Less variation between calves will improve the group’s performance in several ways.

- Social adjustments are easier

- Less bunk displacements (animals pushed away from feed)

- Better marketing opportunities

- Barn dimensions can sometimes be fit to the group

- Grouping calves according to size promotes an all in/all out system. Marketing all calves as a group allows for a barn to be cleaned and rested between groups.

Helpful Tips

- Fresh feed needs to be available 24 hours a day. Cattle on a no roughage feeding program should never run out of feed.

- Make ration changes gradually over the course of a few days.

- Proper ventilation is paramount to animal health and success of the program.

- Stocking density is directly connected to herd health. Higher stocking density is tied to more health issues, higher death loss, and often slower weight gains.

- Clean fresh drinking water is necessary for calves to thrive. Often calves that receive rural water outperform those on well water.

- Persistently wet areas (or mud holes) in pens and lots are a major problem. Mud holes harbor almost every type of bad pathogen and increase infection risk. The mud and pathogens stick to a calf’s hair coat, and then when that calf is licked by a fellow calf, or itself, the licking action causes the calf to ingest pathogens.

- Implanting these calves yields economic and performance advantages. Consult product label for specific recommendations.

- It is a good idea to have a management pen to separate off poor performing calves. Separating the poor performers from the larger group allows these animals to thrive better. Also, when it is time to market your calves it makes it easier to save smaller calves for a later sell date.

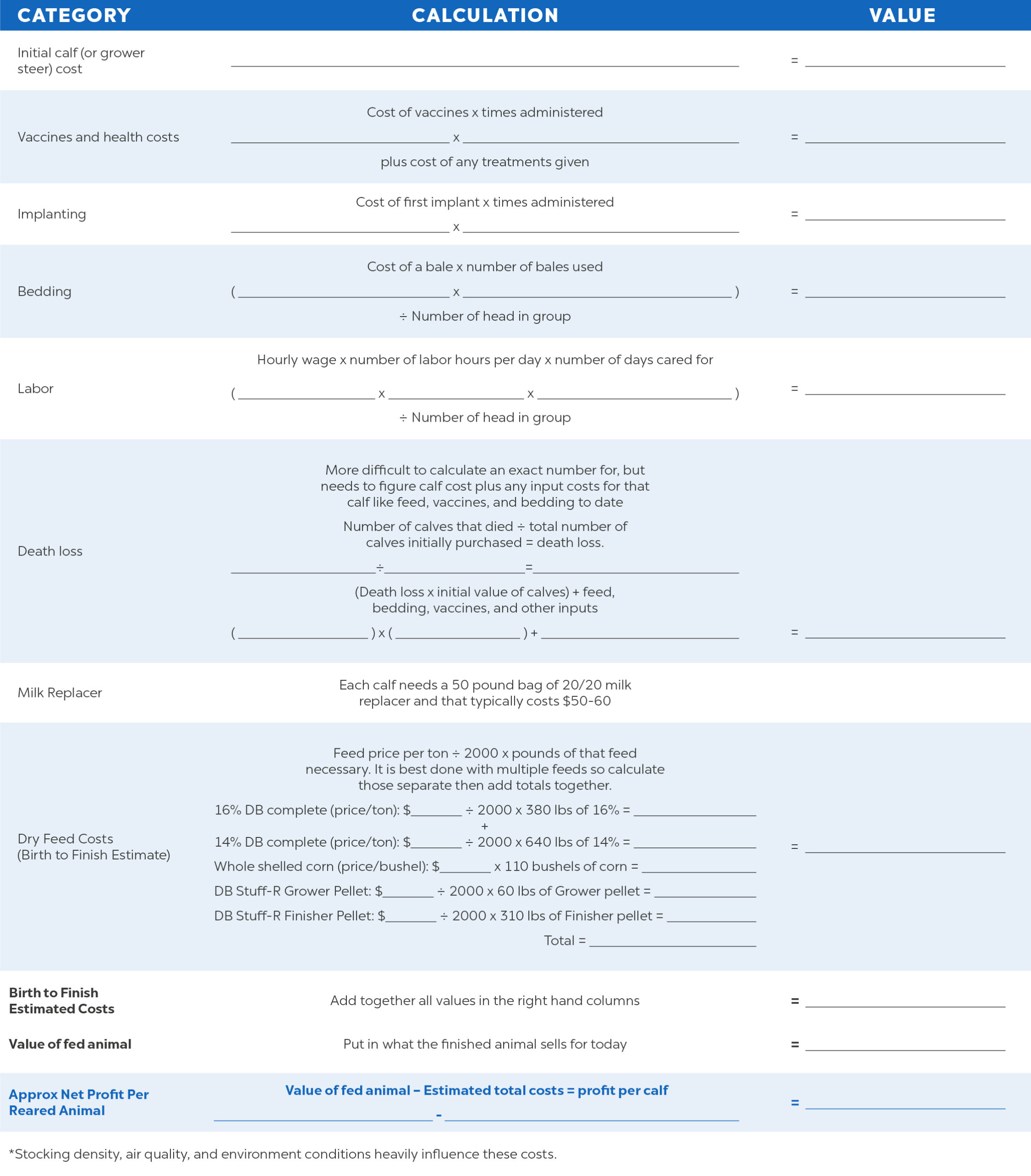

Estimated Costs*

| Category | Calculation | Example Values | Real-Time Values |

|---|---|---|---|

| Initial Holstein steer cost | = ___________ | ||

| Vaccines & health costs | = ___________ | ||

| Implanting | = ___________ | ||

| Bedding (approx. $0.12/head/day) | = ___________ | ||

| Labor ($0.25/d) | = ___________ | ||

| Death loss (est 6%) | = ___________ | ||

| Milk Replacer | = ___________ | ||

| Dry Feed costs | $275/2000 x 380 pounds of 16% = $52.25 $240/2000 x 640 pounds of 14% = $76.80 | = ___________ | |

| Total Estimated Costs |

| Expenses Per Pound of Live Weight | = ___________ | ||

| Value of a 435 Pound Holstein Steer | = ___________ | ||

| Approx Net Profit Per Reared Calf | = ___________ |

|---|

*These costs are just estimates. Market conditions continuously fluctuate for feed and live animals. Any specific economic model must be created on an individual basis. For help creating an economic model specific to your operation contact the nutritionists at NEMO Feed. 660-892-4537; www.nemofeed.com

COMMON HEALTH-RELATED ILLNESSES

Observe calves daily for drinking speed, breathing rates, and manure consistency. If there are changes in any of the items listed, take the calf’s temperature and determine if the calf has scours, respiratory disease, or something else going on. Temperature above 103°F should be given a NSAID and broad-spectrum antibiotic.

Scours

SYMPTOMS

Looseness of bowels and thin off colored feces that are foul-smelling. Dehydrated animal.

TREATMENT

The cause of the scours can vary, but common treatments are labeled use of Corid and Panacur. Feed electrolytes to scoured calves because the animal can quickly dehydrate. It works well to offer electrolytes 20 minutes before feeding milk, but continue to feed milk on schedule.

Respiratory Disease/Pneumonia

SYMPTOMS

High temperature, coughing, rapid breathing, and lethargic actions.

TREATMENT

Make sure housing system is ventilated, but without drafts. Some respiratory disease will occur in every group, develop a treatment program with a veterinarian who has calf-raising experience.

Bloat

SYMPTOMS

Buildup of gas inside the gut organs that visually bulges the side of the animal. It can be a life threatening condition because it prevents the animal from breathing correctly.

TREATMENT

Prevention is best. Make sure feeding times are regular, provide plenty of water, limit slug feeding events, and make sure milk is being fed at around 103°F. Consult veterinarian for advice on stomach tubes or oral antibiotics and pain management.

Pink Eye, Foot Trouble, or Other

SYMPTOMS

Cloudy and runny eyes. Swollen and painful feet. Loss of appetite and body weight.

TREATMENT

Provide fresh, clean, dry environment. Get rid of mud holes. Appropriate antibiotic therapy to control the infection/ inflammation before permanent damage is developed. Control flies and pathogens via spray, tapes, and general cleanliness.

Grower & Finisher Guide: 5 Months to Finished

Dairy steers and dairy-beef crossed animals are a valuable co-product to dairy production. To achieve the best return on investment from dairy beef, one needs to manage them different than a native beef animal.

The goal of our program is to promote animal health and performance in order to maximize growth rate and minimize ownership time. NEMO Feed clients finish dairy beef animals at around 15 months old.

The NEMO Feed Dairy Beef Stuff-R Grower and Finisher Program uses specially formulated pellet supplements that are mixed with whole shelled dry corn to become a complete feeding program from birth to finishing. For ease of management, forage of any type is often never fed to these animals.

Advantages

- Corn is a less expensive energy source than hay, or other forages. And corn is easier to source and handle. The ability to use home grown corn lowers mixing charges from feed mills and brings a competitive advantage.

- Using an all concentrate corn plus pellet blend maximizes growth rate which decrease number of days on feed.

- This program leverages self-feeders and j-bunks to keep equipment needs simple, and labor costs low.

FEEDING PROGRAM

Feeding Directions

Thoroughly mix appropriate amounts of the appropriate pellet with whole shelled corn, according to feeding table below. The complete feed will look like the picture above.

| Animal Weight & Age | DB Stuff-R Grower Pellet | Oats | Whole Shell Corn | Approx. Daily Intake Range |

| 435–600 lbs 5–7 mths | 280 | 1,720 | 12-15 lbs | |

| 600–800 lbs 7–9 mths | 125 | 1,875 | 15-17 lbs | |

| 800–1,000 lbs 9–11 mths | 110 | 1,890 | 17-20 lbs | |

| 1,000–1,200 lbs 11–13 mths | 90 | 1,910 | 20-23 lbs | |

| 1,200–1400 lbs 13 mths–market | 80 | 1,920 | 23-27 lbs | |

The daily intake column is just a guide, offer feed free choice so that animals never run out and expect intake to fluctuate with environment conditions.

Never run animals out of feed.

For feeding calves smaller than 435 pounds, see NEMO Feed’s Young Calf Guide.

MANAGEMENT BEST PRACTICES

Receiving Calf Care

Using an “all-in, all-out system” provides the best opportunity to thoroughly clean barns in between groups of calves.

Preconditioning typically includes weaned before shipping, vaccinated, dehorned, castrated, implanted, and accustomed to a feed bunk. Dairy beef grower phase steers are almost always preconditioned making them healthier and easier to receive. If animals are not pre-conditioned, try to work with calf supplier to receive preconditioned calves.

Vaccination & Health Management

Most vaccination should have been done during the calf stage.

With purchased calves or calves of unknown background, to ensure protection, vaccinate promptly against IBR, PI3, BVD and BRSV, which cause shipping fever. Work with an experienced veterinarian to develop a receiving vaccination program.

Vaccinate all received calves against clostridial diseases.

Palpate scrotum and castrate the stags. Dehorn right away if not yet dehorned.

Implants are recommended. Multiple products exist so consult product label. Implanting with a long acting implant is an efficient tool to decrease re-implanting needs during growth stages.

Building Design

Housing conditions can rob average daily gain in the winter if not managed well with dairy beef. Dairy animals have thinner hides so more shelter is needed compared to traditional beef calves. Here are some tips for designing feeding facilities:

- Minimize the amount of walking

- Wind breaks are required during winter

- Bedded shelter is needed to escape winter weather

Well-ventilated barns usually have one open side and sliding panels or curtains on the closed side to allow for proper ventilation. The most common cause of respiratory problems in growing cattle is not cold temperatures but high humidity due to inadequate ventilation in the housing area.

Bedding

Conventional bedding sources for growing animals are corn stalks, straw, rice hulls, and soybean stubble. The key is for the bedding to be dry so that it absorbs moisture and the animals stay dry.

Wet conditions rob daily gain. If the animals stay dry they can thrive through some extremely cold temperatures. Wet and saturated bedding will also grow many types of bad pathogens. Those pathogens stick to the animal’s hair coats, and when the animals lick each other they will ingest those pathogens leading to sick cattle.

Wet bedding also radiates ammonia which increases the risk of bovine respiratory disease (BRD).

Bedding Goals

- Dry

- Clean

- Provides insulation during cold weather

- Minimizes fly nesting areas

Size Grouping Is Important

Group calves according to size and age. This is best achieved when barns can be filled quickly. Less variation between calves will improve the group’s performance in several ways:

- Social adjustments are easier

- Less bunk displacements (animals pushed away from feed)

- Better marketing opportunities

- Barn dimensions can sometimes be fit to the group

Helpful Tips

- Fresh feed needs to be available 24 hours a day. Cattle on a no roughage feeding program should never run out of feed.

- Make ration changes gradually over the course of a few days.

- Proper ventilation is paramount to animal health and success of the program. This consists of dry draft free housing.

- Clean fresh drinking water is necessary for animals to thrive.

- Implanting these animals yields economic and performance advantages.

Estimated Costs*

| Category | Calculation | Example Values | Real-Time Values |

|---|---|---|---|

| Initial Holstein steer cost | = ___________ | ||

| Vaccines & health costs | = ___________ | ||

| Implanting | = ___________ | ||

| Bedding (approx. $0.12/head/day) | = ___________ | ||

| Labor ($0.20/d) | = ___________ | ||

| Death loss (est 6%) | = ___________ | ||

| Dry Feed costs | $130/2000 x 6,250 lbs of Corn = $406.25 $540/2000 x 60 lbs of Grower Pellet = $16.20 $650/2000 x 310 lbs of Finisher Pellet = $100.75 | = ___________ | |

| Total Estimated Costs |

| Expenses Per Pound of Live Weight | = ___________ | ||

| Value of a 1,400 Pound Holstein Steer | = ___________ | ||

| Approx Net Profit Per Reared Calf | = ___________ |

|---|

*These costs are just estimates. Market conditions continuously fluctuate for feed and live animals. Any specific economic model must be created on an individual basis. For help creating an economic model specific to your operation contact the nutritionists at NEMO Feed. 660-892-4537; www.nemofeed.com

COMMON HEALTH-RELATED ILLNESSES

Preconditioned and heavier dairy beef animals tend to have fewer health problems. Still respiratory and digestive diseases can show up in cattle of all sizes. Observe steers daily for general appetite, breathing rates, and manure consistency.

Respiratory Disease/Pneumonia

SYMPTOMS

High temperature, coughing, rapid breathing, and lethargic actions.

TREATMENT

Make sure housing system is ventilated but without drafts. Consult veterinarian for antibiotic treatments. Chlortetracycline (Aureomycin) or oxytetracycline (Terramycin) can combat respiratory issues with veterinarian approval.

Acidosis

SYMPTOMS

Low feed intake, increased breathing, loose manure, dehydration, lethargy, poor performance, and can lead to death.

TREATMENT

Follow a consistent routine for feeding and avoid anything that will lead to a slug feeding event such as running animals out of feed or water, or locking them away from feed. Avoid cracked or ground corn – fine particles increase acidosis risk. Straw or dry hay at 2 pounds per head combats acidosis, but displaces grain consumption and lowers daily gain.

Bloat

SYMPTOMS

Buildup of gas inside the gut organs that visually bulges the side of the animal. It can be a life threatening condition because it prevents the animal from breathing correctly.

TREATMENT

Prevention is best. Make sure feeding times are regular, provide plenty of water, and limit slug feeding events.

Pink Eye, Foot Trouble, or Other

SYMPTOMS

Cloudy and runny eyes. Swollen and painful feet. Loss of appetite and body weight.

TREATMENT

Provide fresh, clean, dry environment. Get rid of mud holes. Appropriate antibiotic therapy to control the infection and inflammation before permanent damage is developed. Control flies and pathogens via spray, tapes, and general cleanliness.

Economics of Dairy Beef